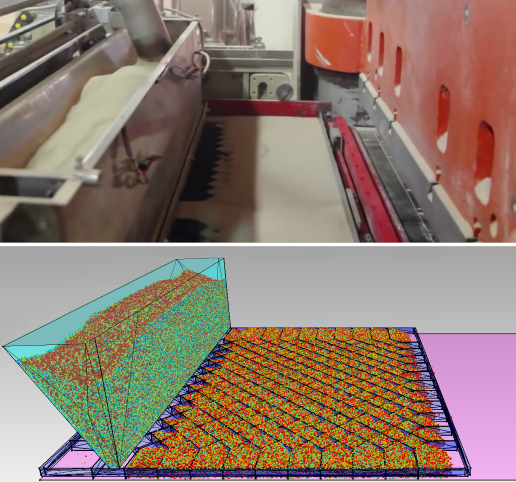

Capture what's really happening in your industrial process

What is ScaleDEM?

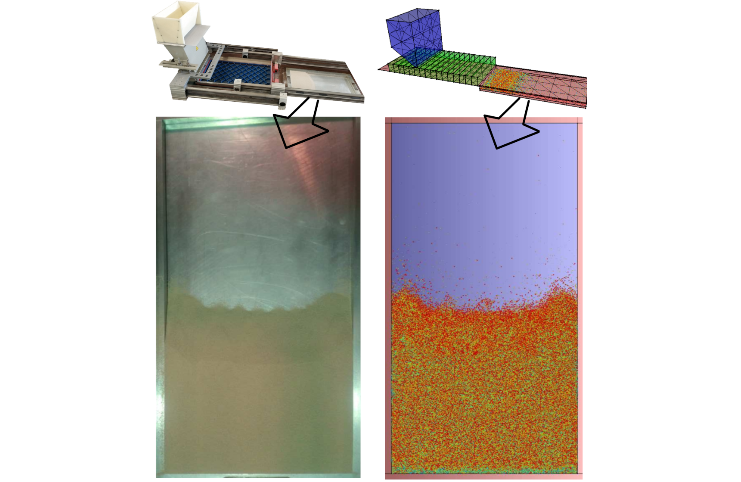

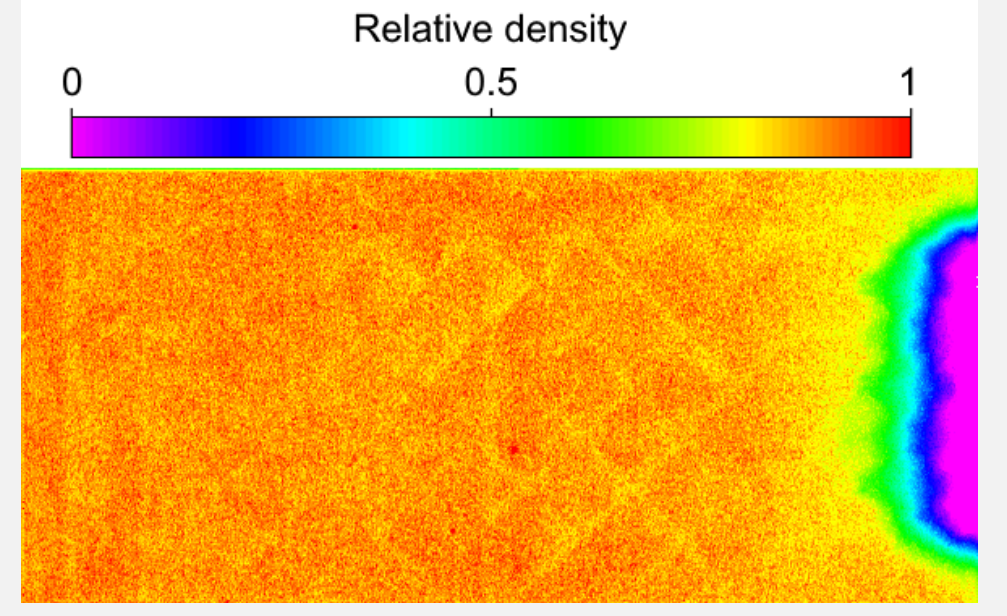

ScaleDEM is a modular granular material simulation software. The main benefits of its use are an improved understanding of powder handling equipment and its virtual prototyping.

Unlike other software, ScaleDEM is designed to be expanded through customized modules. Depending on your equipment or process to be analysed, we will prepare the modules so that you can easily operate the software yourself.

Whether it is optimising equipment design, optimising operating conditions or understanding what is happening in your process, we will provide you with the tool you need, designed specifically for you.

Learn moreThe aims of ScaleDEM

ScaleDEM is a modelling platform consisting of a base module and a set of customized independent modules.

ScaleDEM is a customer-oriented software product, providing you precise data to improve your industrial process.

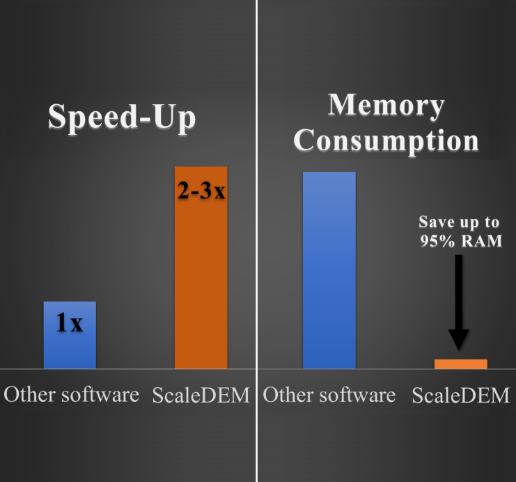

Avoid using clusters and cloud computing. ScaleDEM is specially adapted to run in personal computers.

High impact scientific publications support ScaleDEM and our working methodology.

Why ScaleDEM?

Our capabilities

Definition and analysis of the process variables, materials and the scales involved. It includes the particles analysis to select the most suitable powder model.

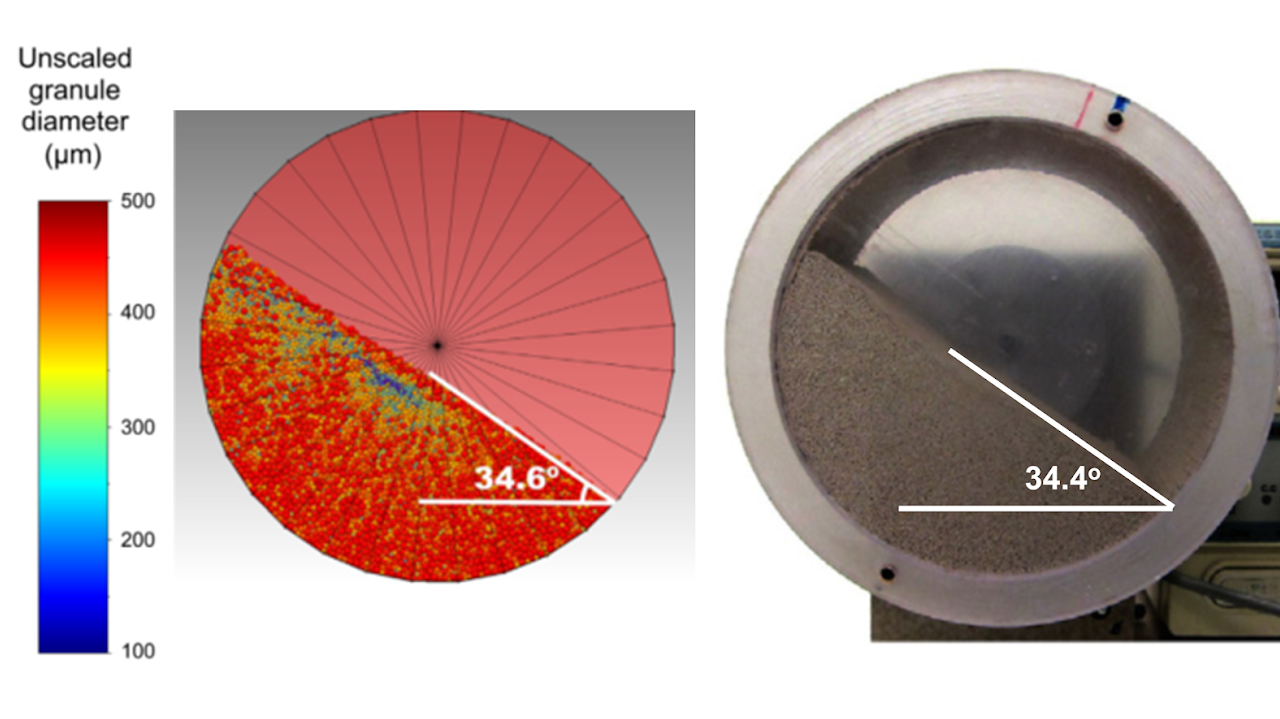

The parameters of the rheological model of the powder are identified and validated by means of dynamic tests.

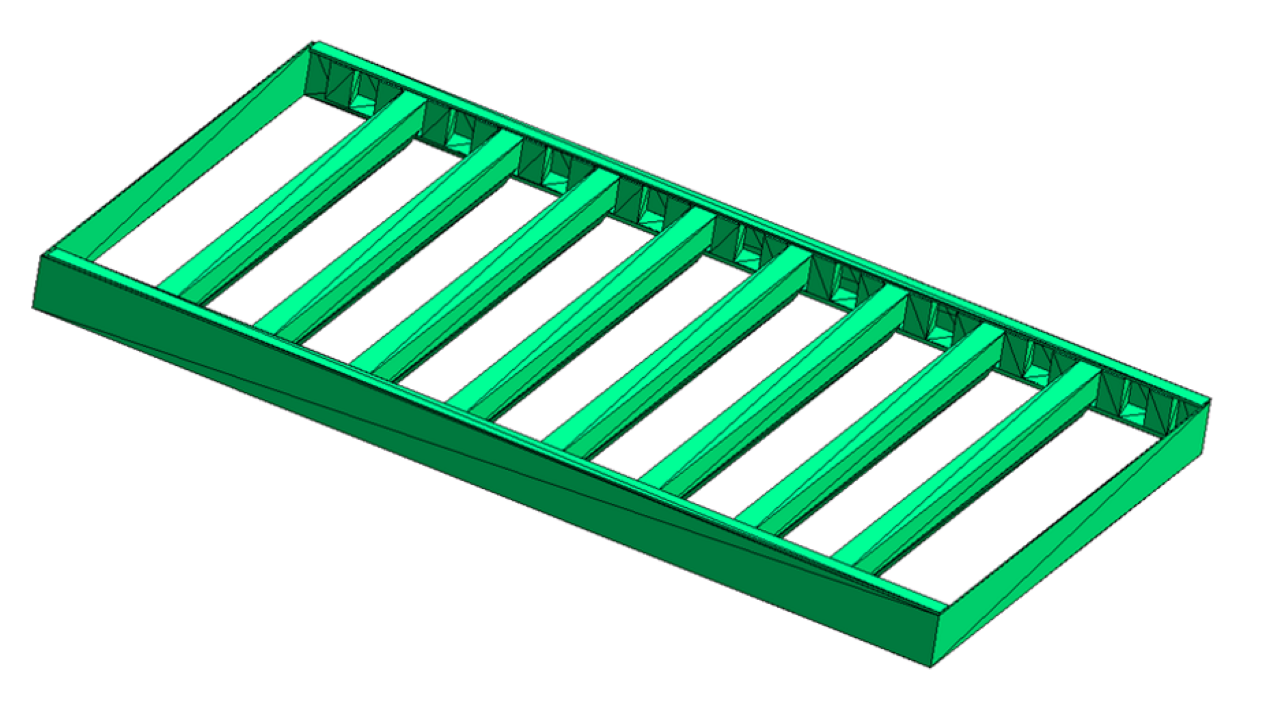

Using CAD, the components of the particular industrial process are prepared to run the simulations.

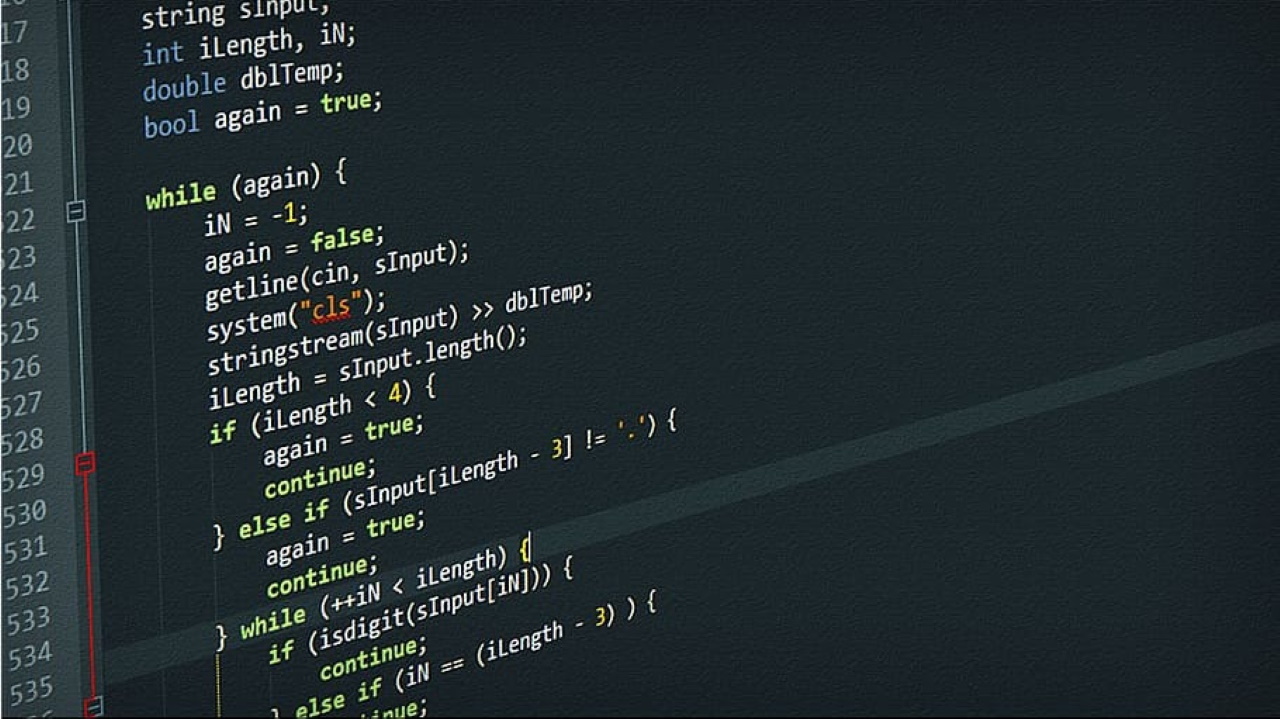

ScaleDEM is expandable through customized modules. These modules can cover different types of features, for example, interparticle contact models, post-processing options, execution batch scheduler, etc.

We help you to interpret the results of your model and report the technical aspects. We provide you with documentation, easy-to-follow examples and practical manuals to exploit your modules.

Based on our experience, we can provide a list of recommendations to improve your process.

Core team

Ph.D in Chemical Engineering.

Senior researcher in Modelling and Industrial Processes at ITC

Ph.D in Physics.

Professor in Computational Mechanics at UGent-MMS group.

Get in touch

ITC-AICE

Pol. Ind. SUPOI 8. C/ Cedrillas, nº 20

12550 Almassora – Castelló, Spain

UGent-MMS

Tech Lane Ghent Science Park – Campus A, Technologiepark Building 46

9052 Zwijnaarde - Ghent, Belgium